Transforming waste to value

Turning yesterday’s waste into tomorrow’s packaging

At Recinloop, we convert ethically sourced post-consumer and post-industrial plastic waste into high-quality recycled resins.

Our Advanced Technology

Our 3D process: De-inking, De-oiling & De-odorizing creates recycled resins that match the quality of virgin plastics.

URep & EPR Compliance

We provide solutions to help brands meet Use of Recycled Plastics (URep) & Extended Producer Responsibility (EPR) requirements.

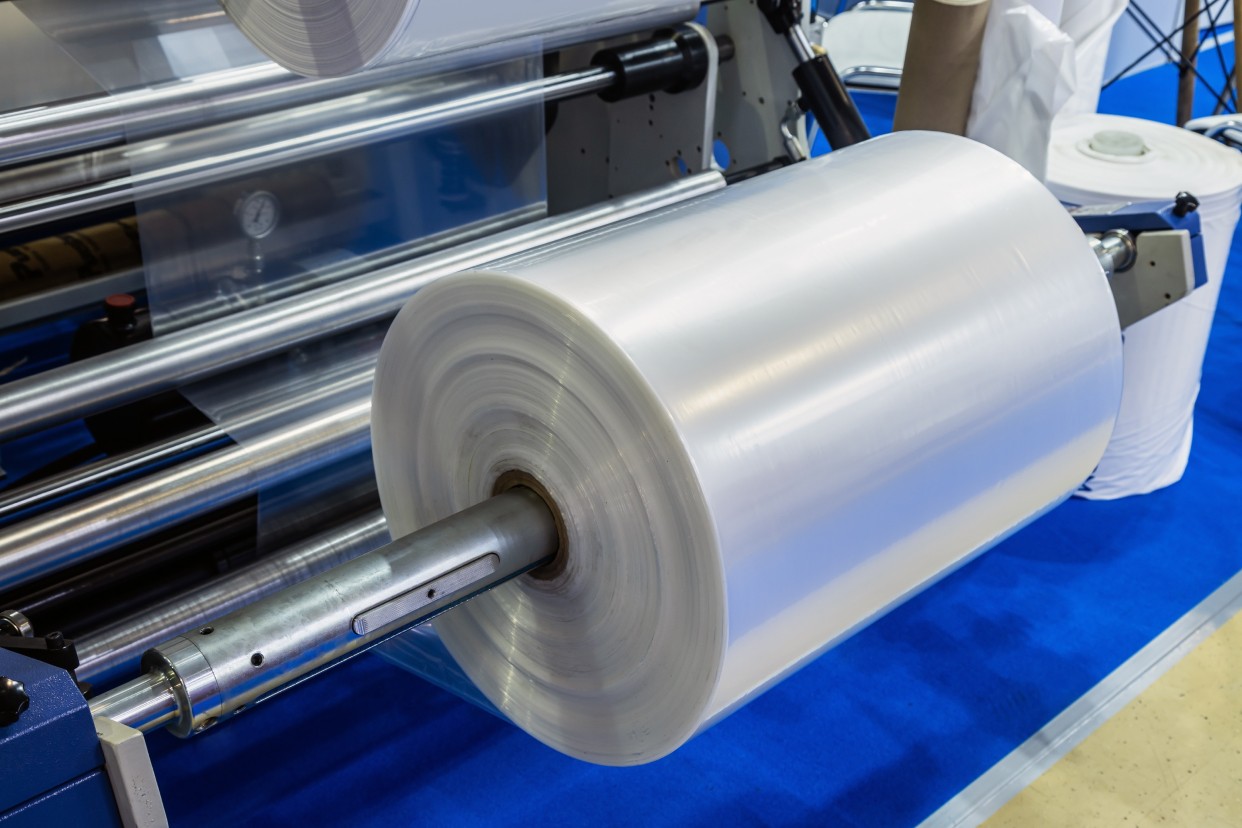

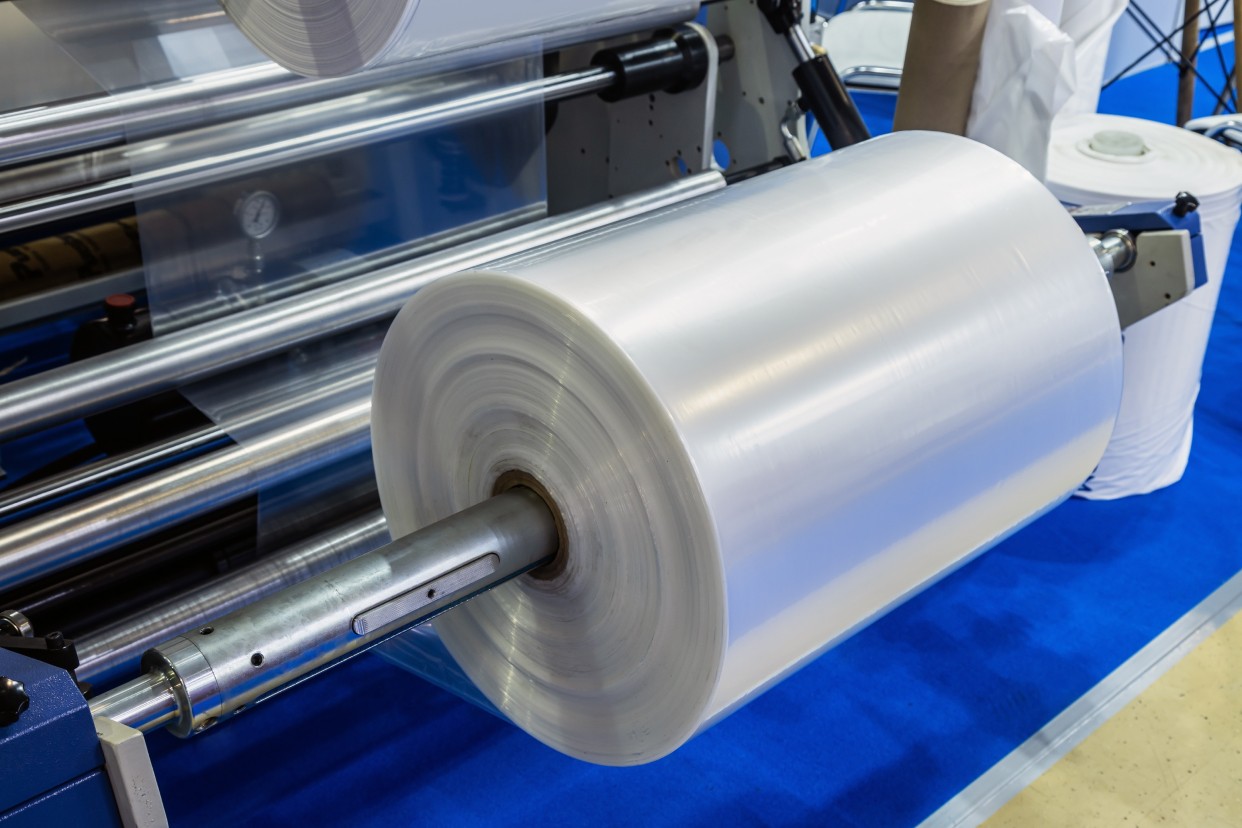

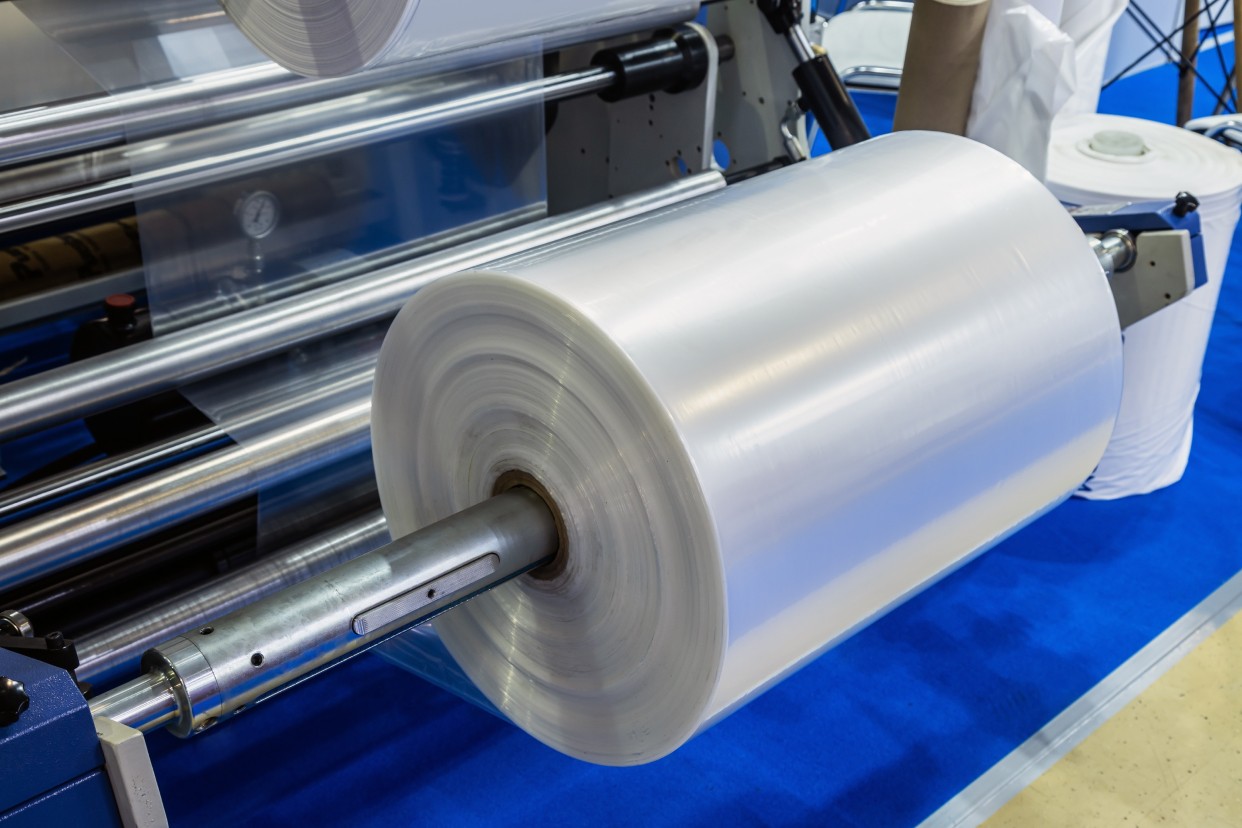

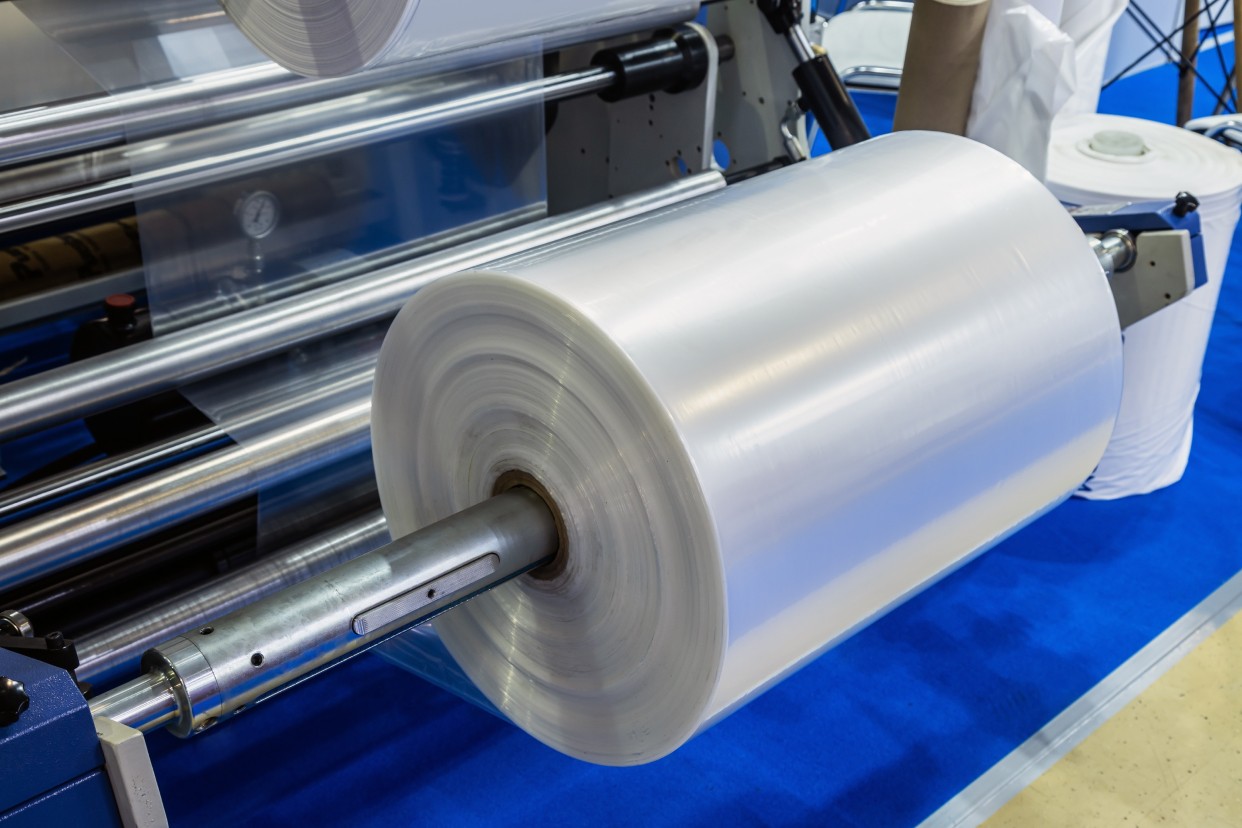

Leading the path in high quality recyclable resins

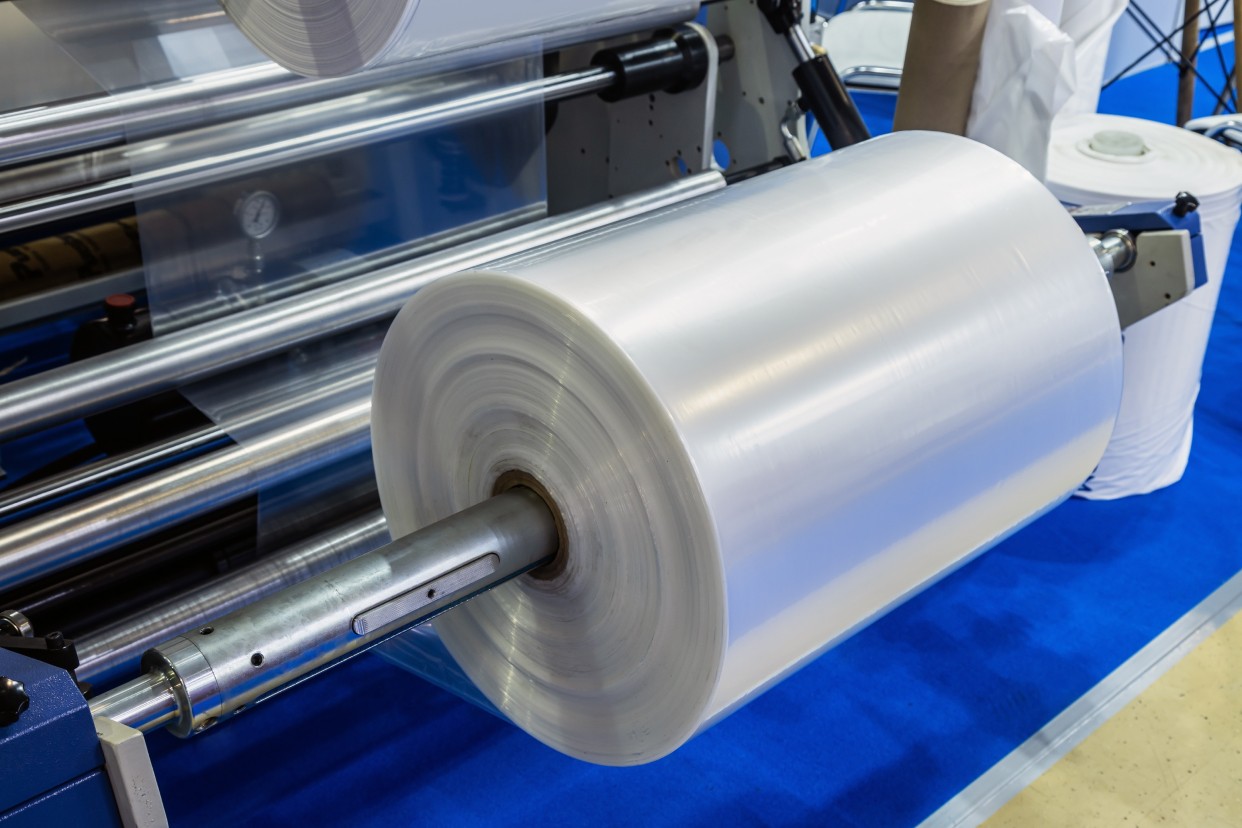

Our resins can be used to make transparent flexible packaging and offer high tensile strength at par with virgin polymers due to our state of the art integrated process that removes all the contaminants in one go.

High Tensile

Strength

High Transparency

Quality Equivalent

to Virgin

100% Traceability

Resins to cover all your flexible packaging needs

EcoRecin - PE

These resins are made using flexible polyethylene plastic waste and can be used to substitute virgin polyethylene in varies applications with upto 100% substitution.

Applications:

Secondary or Tertiary Printed Packaging

All Flexible Single-Use Plastics (SUPs)

Non-Food Contact Flexible Packaging

Transit packaging

Shrink Films

Stretch Films

EcoRecin - PP

These resins are made using flexible polypropylene plastic waste and can be used to substitute virgin polypropylene in varied applications with upto 100% substitution.

Applications:

Biaxially Oriented Polypropylene (BOPP) Films

Garment bags

Non-Food Contact MLP

Cast Polypropylene (CPP) films

Flow Wraps

Non-Food Contact Flexible Packaging

Our Sourcing strength

Maintaining quality through our trusted network

Our resins are produced with consistent quality through a robust supply chain. By partnering with waste aggregators, retail shops, and waste management companies, we secure a reliable flow of raw materials, ensuring uninterrupted production and meeting your needs consistently.

Helping companies achieve their EPR targets, effectively!

Under Extended Producer Responsibility (EPR), companies must include recycled content in plastic packaging, with requirements set to increase. RecinLoop supports this shift by creating high-quality recycled resins. These resins integrate smoothly into existing manufacturing processes.

Diversify your business with Recinloop's green credit offsets

Coming soon.

Transforming waste to value

Partnering with top Indian, international FMCG brands, and specifiers to achieve a complete circular loop system for flexible secondary packaging. Thank you for your interest!

Get in touch with us

Let’s be a part of the sustainable future of plastic

Email us

support@recinloop.com

Contact us

+91 997 185 7576

Visit us

Office address- 2nd Floor, No.407, 6th A Cross, 12th Main, Sadashiva Nagar, Bengaluru 560 080

Factory address- Plot No. 214-217, 3RD Phase, Malur KIADB Industrial Area, Malur, Karnataka

Industries we serve

We work with global and Indian brands to create a sustainable circular loop in flexible packaging, providing high-quality recycled resins for various industries.

Fast Moving Consumer

Goods (FMCG)

Garment

Industry

Flexible

Packaging

Our ETHOS

Helping brands achieve Plastic Neutrality

50,000+ kg

Virgin plastic replaced

200+

Collection partners

20+

Strategic Brand Alliance partnership

Transforming waste to value

Turning yesterday’s waste into tomorrow’s packaging

At Recinloop, we convert ethically sourced post-consumer and post-industrial plastic waste into high-quality recycled resins.

Advanced De-Inking & Deodorising

Our process produces recycled resins that are at par with virgin plastic standards.

URep & EPR Compliance

We provide solutions to help brands meet Use of Recycled Plastics (URep) & Extended Producer Responsibility (EPR) requirements.

Leading the path in high quality recyclable resins

Our resins can be used to make transparent flexible packaging and offer high tensile strength at par with virgin polymers due to our state of the art integrated process that removes all the contaminants in one go.

High Tensile Strength

High Transparency

Quality Equivalent to Virgin

100% Traceability

Resins to cover all your flexible packaging needs

EcoRecin - PE

These resins are made using flexible polyethylene plastic waste and can be used to substitute virgin polyethylene in varies applications with upto 100% substitution.

Applications:

Secondary or Tertiary Printed Packaging

All Flexible Single-Use Plastics (SUPs)

Non-Food Contact Flexible Packaging

Transit packaging

Shrink Films

Stretch Films

EcoRecin - PP

These resins are made using flexible polypropylene plastic waste and can be used to substitute virgin polypropylene in varied applications with upto 100% substitution.

Applications:

Biaxially Oriented Polypropylene (BOPP) Films

Garment bags

Non-Food Contact MLP

Cast Polypropylene (CPP) films

Flow Wraps

Non-Food Contact Flexible Packaging

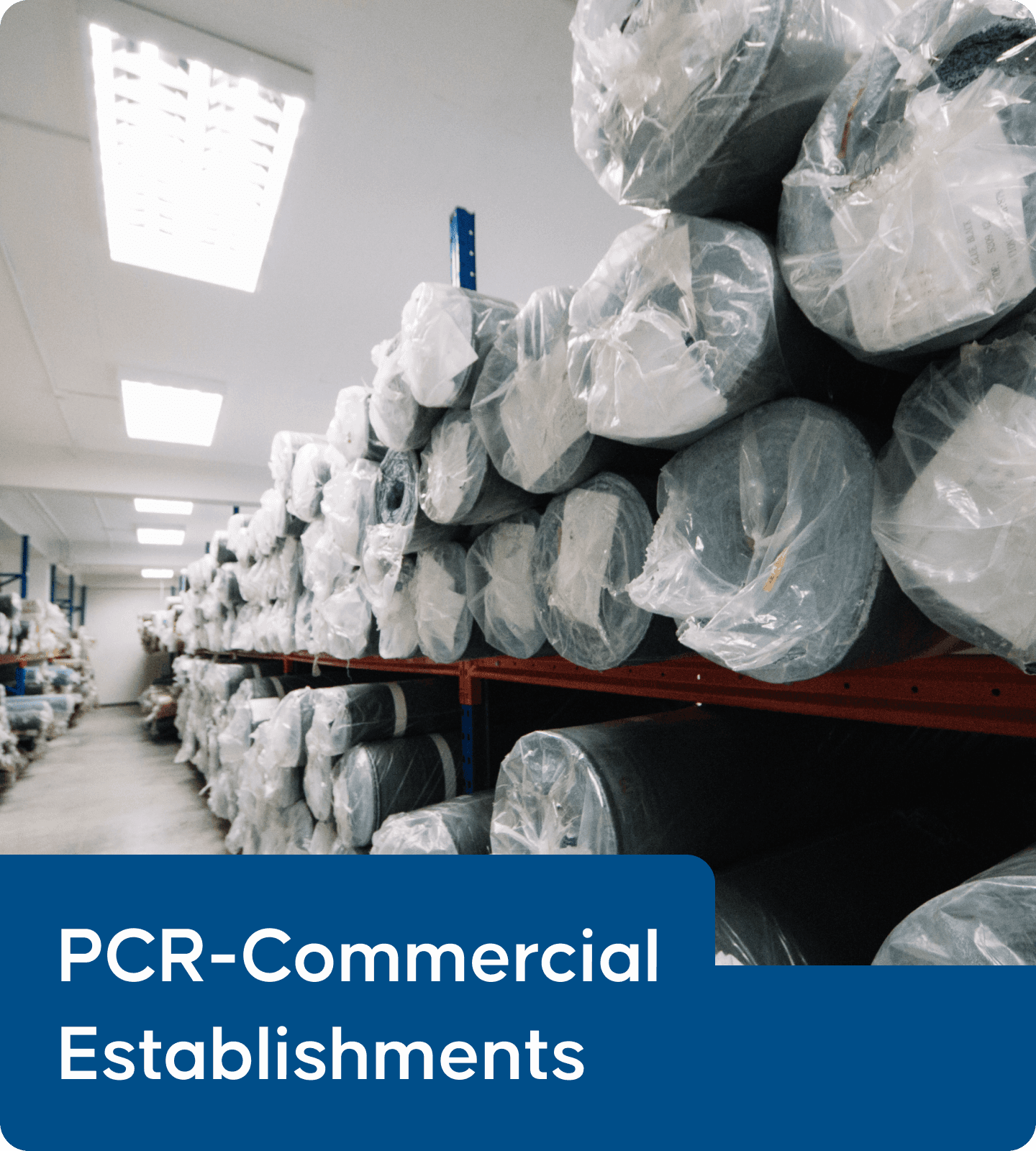

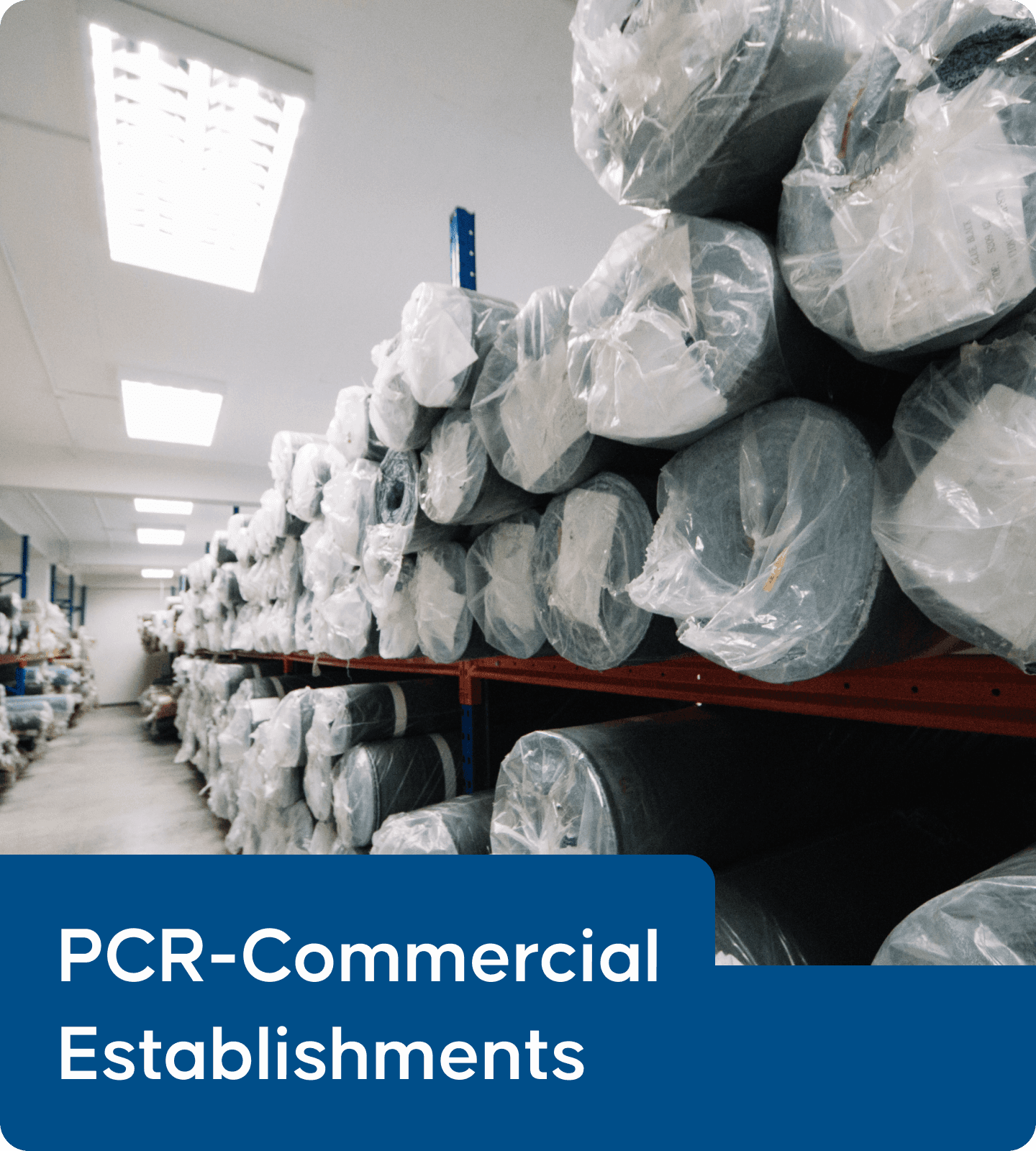

Our Sourcing strength

Maintaining quality through our trusted network

Our resins are produced with consistent quality through a robust supply chain. By partnering with waste aggregators, retail shops, and waste management companies, we secure a reliable flow of raw materials, ensuring uninterrupted production and meeting your needs consistently.

Helping companies achieve their EPR targets, effectively!

Under Extended Producer Responsibility (EPR), companies must include recycled content in plastic packaging, with requirements set to increase. RecinLoop supports this shift by creating high-quality recycled resins. These resins integrate smoothly into existing manufacturing processes.

Diversify your business with Recinloop's green credit offsets

Coming soon.

Transforming waste to value

Partnering with top Indian, international FMCG brands, and specifiers to achieve a complete circular loop system for flexible secondary packaging. Thank you for your interest!

Get in touch with us

Let’s be a part of the sustainable future of plastic

Email us

support@recinloop.com

Contact us

+91 997 185 7576

Visit us

Office address- 2nd Floor, No.407, 6th A Cross, 12th Main, Sadashiva Nagar, Bengaluru 560 080

Factory address- Plot No. 214-217, 3RD Phase, Malur KIADB Industrial Area, Malur, Karnataka

Industries we serve

We work with global and Indian brands to create a sustainable circular loop in flexible packaging, providing high-quality recycled resins for various industries.

Fast Moving Consumer

Goods (FMCG)

Fast Moving Consumer

Goods (FMCG)

Garment

Industry

Garment

Industry

Flexible

Packaging

Flexible

Packaging

Our ETHOS

Helping brands achieve Plastic Neutrality

50,000+ kg

Virgin plastic replaced

200+

Collection partners

20+

Strategic Brand Alliance partnership

Transforming waste to value

Turning yesterday’s waste into tomorrow’s packaging

At Recinloop, we convert ethically sourced post-consumer and post-industrial plastic waste into high-quality recycled resins.

Advanced De-Inking & Deodorising

Our process produces recycled resins that are at par with virgin plastic standards.

URep & EPR Compliance

We provide solutions to help brands meet Use of Recycled Plastics (URep) & Extended Producer Responsibility (EPR) requirements.

Leading the path in high quality recyclable resins

Our resins can be used to make transparent flexible packaging and offer high tensile strength at par with virgin polymers due to our state of the art integrated process that removes all the contaminants in one go.

High Tensile

Strength

High Transparency

Quality Equivalent to Virgin

100% Traceability

Resins to cover all your flexible packaging needs

EcoRecin - PE

These resins are made using flexible polyethylene plastic waste and can be used to substitute virgin polyethylene in varies applications with upto 100% substitution.

Applications:

Secondary or Tertiary Printed Packaging

All Flexible Single-Use Plastics (SUPs)

Non-Food Contact Flexible Packaging

Transit packaging

Shrink Films

Stretch Films

EcoRecin - PP

These resins are made using flexible polypropylene plastic waste and can be used to substitute virgin polypropylene in varied applications with upto 100% substitution.

Applications:

Biaxially Oriented Polypropylene (BOPP) Films

Garment bags

Non-Food Contact MLP

Cast Polypropylene (CPP) films

Flow Wraps

Non-Food Contact Flexible Packaging

Our Sourcing strength

Maintaining quality through our trusted network

Our resins are produced with consistent quality through a robust supply chain. By partnering with waste aggregators, retail shops, and waste management companies, we secure a reliable flow of raw materials, ensuring uninterrupted production and meeting your needs consistently.

Helping companies achieve their EPR targets, effectively!

Under Extended Producer Responsibility (EPR), companies must include recycled content in plastic packaging, with requirements set to increase. RecinLoop supports this shift by creating high-quality recycled resins. These resins integrate smoothly into existing manufacturing processes.

Diversify your business with Recinloop's green credit offsets

Coming soon.

Transforming waste to value

Partnering with top Indian, international FMCG brands, and specifiers to achieve a complete circular loop system for flexible secondary packaging. Thank you for your interest!

Get in touch with us

Let’s be a part of the sustainable future of plastic

Email us

support@recinloop.com

Contact us

+91 997 185 7576

Visit us

Office address- 2nd Floor, No.407, 6th A Cross, 12th Main, Sadashiva Nagar, Bengaluru 560 080

Factory address- Plot No. 214-217, 3RD Phase, Malur KIADB Industrial Area, Malur, Karnataka

Industries we serve

We work with global and Indian brands to create a sustainable circular loop in flexible packaging, providing high-quality recycled resins for various industries.

Fast Moving Consumer

Goods (FMCG)

Fast Moving Consumer

Goods (FMCG)

Garment

Industry

Garment

Industry

Flexible

Packaging

Flexible

Packaging

Our ETHOS

Helping brands achieve Plastic Neutrality

50,000+ kg

Virgin plastic replaced

200+

Collection partners

20+

Strategic Brand Alliance partnership